ID Tube Polishing with Abrasive Belts (E)

ID Tube Polishing with Abrasive Belts (E)

Abrasive belts combine ceramic grains and aluminum oxide minerals to perform a variety of stainless steel finishing tasks. The broad, circular head design is perfectly suited for interior diameters of aluminum or stainless steel tubes. For deeper grinding and deburring, choose our coarsest 60 grit grinding belt. For more precise buffing and polishing applications, choose our abrasive belts with grits as fine as 180 particles per square inch.

For more information on available sizes and grits, contact the experienced aluminum and stainless steel finishing suppliers at Waters Industrial today!

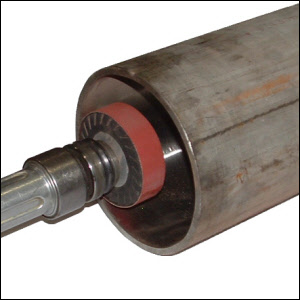

ID Tube Polishing

Contact Wheel / Expander Wheel

Adapter: 3/8-24 to 5/8-11

|

1 x 1-1/2 x 1/4 shank |

NA |

|

2 x 1 x 1/4 shank |

NA |

|

3-1/2 x 1 x 5/8-11 |

|

|

3-1/2 x 1 x 3/8-24 |

NA |

Straight Grinder

Abrasives

Coated Abrasive Belts - 60 grit

Coated Abrasive Belts - 80 grit

Coated Abrasive Belts - 120 grit

Coated Abrasive Belts - 180 grit

Trizact Belts - A100

Trizact Belts - A45

Surface Conditioning Belts - Coarse(Brown)

Surface Conditioning Belts - Med(Maroon)

Contact the metal finishing equipment supplier Waters Industrial today!

For more information about the stainless steel finishing equipment available from stroke sanders to abrasive belts and more.

Phone

(262) 786-1610Hours

Monday - Friday 7am - 4pmSaturday - Sunday Closed